Hello readers, welcome to this informative article about alternator wiring diagram. In this comprehensive guide, we will explore the intricacies of alternator wiring and provide you with step-by-step instructions on how to install it properly. Whether you are a seasoned DIY enthusiast or a beginner in the field, this article will equip you with the necessary knowledge to successfully wire your alternator. So, let’s dive in!

1. Understanding the Basics of Alternator Wiring Diagram

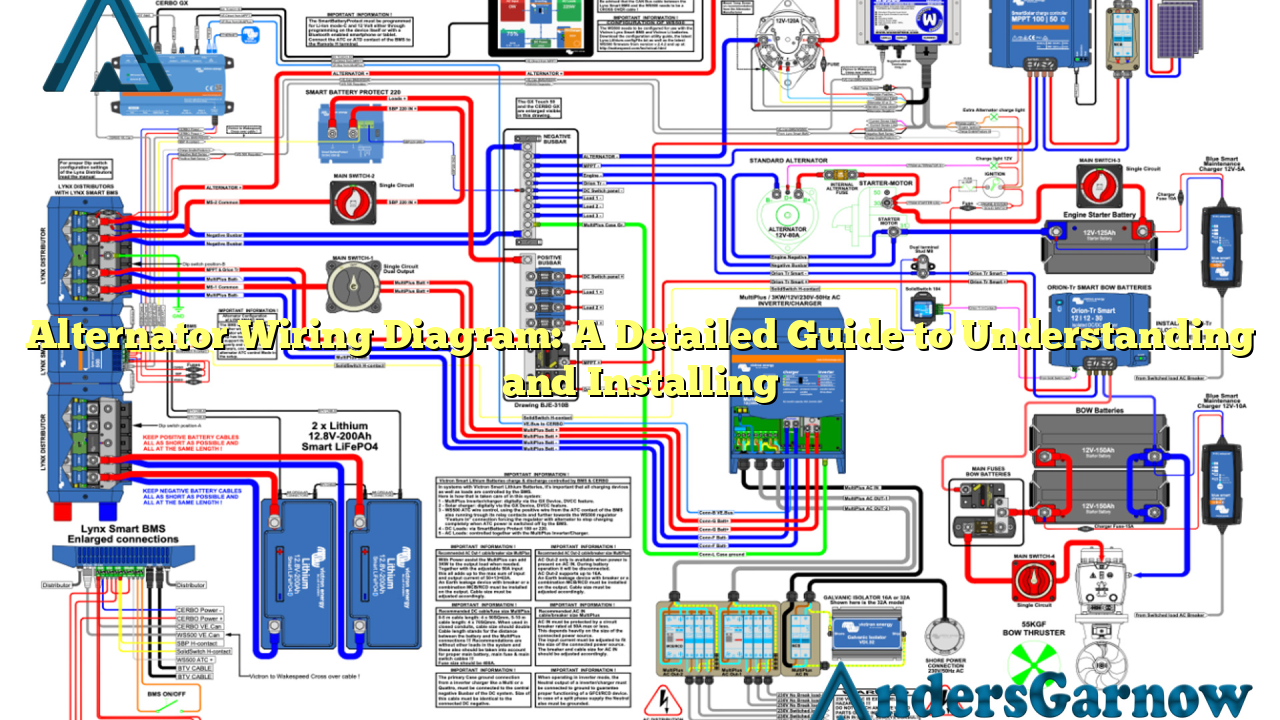

Before we jump into the wiring process, it is essential to understand the fundamental components and functions of an alternator. An alternator is a vital part of a vehicle’s charging system, responsible for converting mechanical energy into electrical energy. It consists of several key components, including the rotor, stator, diode trio, voltage regulator, and battery. Each of these components plays a crucial role in ensuring the proper functioning of the alternator.

When it comes to wiring the alternator, the primary objective is to establish a connection between the alternator and the battery. This electrical connection allows the alternator to recharge the battery while the engine is running, ensuring a continuous supply of power to the vehicle’s electrical system.

Advantages of Alternator Wiring Diagram:

1. Efficient Charging: The alternator wiring diagram ensures that the battery receives a consistent and efficient charge, maximizing its lifespan and performance.

2. Improved Electrical System Functionality: Properly wiring the alternator guarantees a steady supply of power to the electrical components of the vehicle, preventing issues like dimmed lights or malfunctioning devices.

3. Easy Troubleshooting: With a clear wiring diagram, diagnosing and resolving any potential wiring-related problems becomes much simpler, saving you time and money on repairs.

Disadvantages of Alternator Wiring Diagram:

1. Complexity: Wiring an alternator can be a complex task, especially for individuals with limited electrical knowledge. It requires careful attention to detail and following the instructions precisely.

2. Risk of Damage: Incorrect wiring can potentially damage the alternator, battery, or other electrical components of the vehicle. It is crucial to double-check the wiring connections to avoid any mishaps.

3. Compatibility Issues: Different vehicles may have variations in their alternator wiring setups. It is essential to ensure that the wiring diagram you are using matches your specific vehicle make and model.

2. Step-by-Step Guide to Wiring the Alternator

In this section, we will provide you with a detailed step-by-step guide on how to wire the alternator correctly. Please note that the instructions may vary depending on your vehicle’s make and model. It is always recommended to refer to the vehicle’s manual or consult a professional if you are unsure.

Step 1: Disconnect the Battery

Before starting any electrical work, it is crucial to disconnect the negative terminal of the battery to avoid any electrical shock or damage.

Step 2: Locate the Alternator

Identify the alternator’s location in your vehicle. It is typically situated near the engine and connected to various components such as the drive belt and electrical connectors.

Step 3: Remove the Old Alternator

If you are replacing an old alternator, carefully remove it by loosening the mounting bolts, disconnecting the electrical connectors, and removing the drive belt.

Step 4: Install the New Alternator

Position the new alternator in place and secure it by tightening the mounting bolts. Reconnect the electrical connectors and the drive belt.

Step 5: Connect the Wiring

Refer to the wiring diagram specific to your vehicle and establish the necessary connections between the alternator and the battery. Ensure that all connections are secure and properly insulated.

Step 6: Reconnect the Battery

Once the wiring is complete, reconnect the negative terminal of the battery.

Step 7: Test the Alternator

Start the engine and test the alternator’s functionality by measuring the voltage across the battery terminals. It should read around 13.8 to 14.4 volts, indicating that the alternator is charging the battery correctly.

3. Alternative Wiring Methods for Alternators

While the traditional alternator wiring diagram is widely used, there are alternative methods available. One such method is using a one-wire alternator. Unlike the standard wiring setup, a one-wire alternator simplifies the wiring process by eliminating the need for external voltage regulators and complex wiring connections. It is an excellent option for those seeking a straightforward and efficient wiring solution.

Another alternative is the use of a high-output alternator. This type of alternator is designed to provide greater electrical power, making it suitable for vehicles with increased power demands, such as those with aftermarket audio systems or additional lighting. However, installing a high-output alternator may require modifications to the vehicle’s electrical system and wiring setup.

Alternator Wiring Diagram: Complete Information

| Component | Description | Function |

|---|---|---|

| Rotor | A rotating magnetic field | Produces an electromagnetic field |

| Stator | A stationary set of wire coils | Converts the rotating magnetic field into electrical energy |

| Diode Trio | Three diodes | Rectifies the AC current produced by the alternator into DC current |

| Voltage Regulator | An electronic component | Regulates the output voltage of the alternator to a specific level |

| Battery | A rechargeable energy storage device | Stores electrical energy produced by the alternator for later use |

Frequently Asked Questions (FAQ) about Alternator Wiring Diagram

Q: Can I install an alternator without a wiring diagram?

A: While it is possible to install an alternator without a wiring diagram, having a clear and accurate diagram significantly simplifies the process and reduces the risk of errors.

Q: Where can I find the wiring diagram for my vehicle’s alternator?

A: The wiring diagram for your specific vehicle can usually be found in the vehicle’s manual or obtained from the manufacturer’s official website. Additionally, there are online resources and automotive forums where you can find wiring diagrams for various vehicle makes and models.

Q: What tools do I need to wire an alternator?

A: The tools required may vary depending on the specific vehicle and wiring setup. However, common tools needed for wiring an alternator include a socket set, wire cutters, wire strippers, electrical tape, and a multimeter for testing purposes.

Conclusion

In conclusion, understanding the alternator wiring diagram is crucial for a successful installation and proper functioning of your vehicle’s charging system. By following the step-by-step guide provided in this article, you can confidently wire your alternator and ensure a reliable power supply to your vehicle’s electrical components. Remember to refer to the specific wiring diagram for your vehicle and take all necessary safety precautions during the installation process. Happy wiring!