Hello there, esteemed readers! Today, we delve into the world of mechanic wiring, a crucial aspect of electrical systems. In this article, we will explore the ins and outs of mechanic wiring, its advantages and disadvantages, as well as alternative approaches. So, fasten your seatbelts and let’s embark on this electrifying journey!

1. Understanding Mechanic Wiring

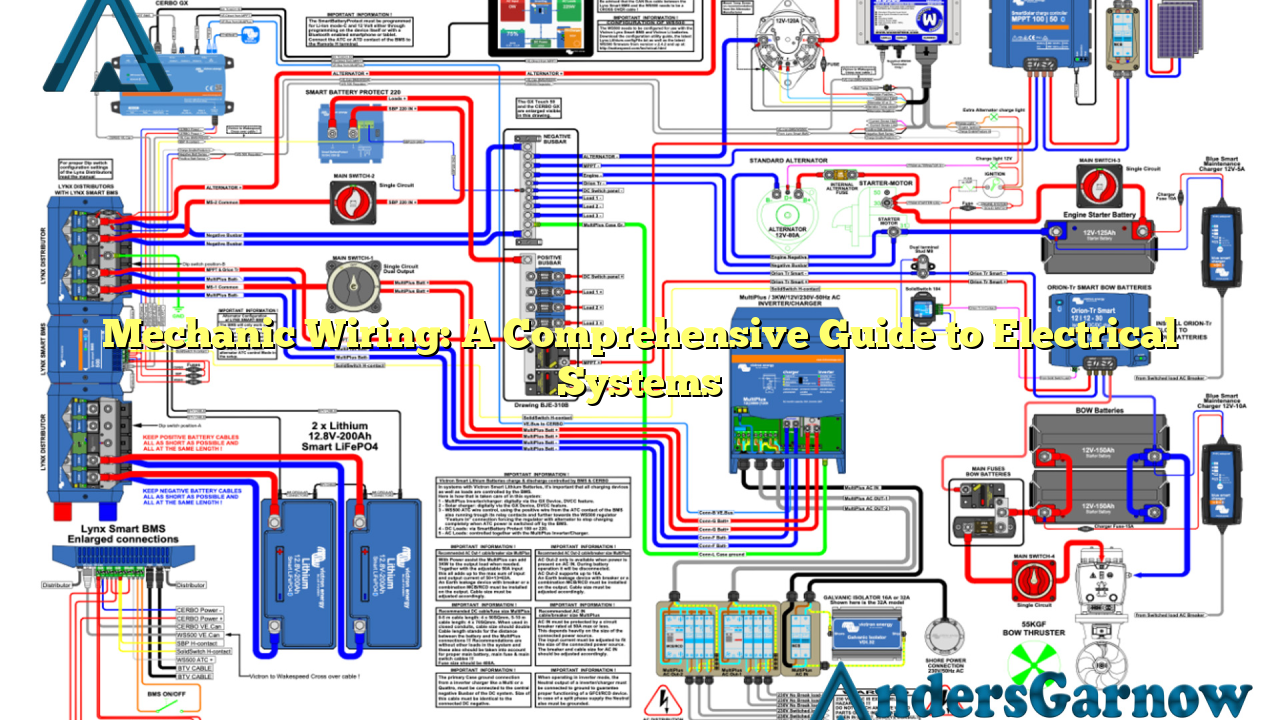

Mechanic wiring refers to the intricate network of electrical connections within a mechanical system. It involves the installation, maintenance, and repair of electrical circuits, switches, and other components in various machines, vehicles, and equipment. This complex system ensures the smooth operation and functionality of modern mechanical systems.

2. The Advantages of Mechanic Wiring

One of the key advantages of mechanic wiring is its reliability. Properly installed and maintained wiring systems ensure consistent electrical power supply, reducing the risk of malfunctions and downtime. Additionally, mechanic wiring allows for efficient energy distribution, optimizing the performance of mechanical systems.

Another benefit of mechanic wiring is its flexibility. With the right wiring design, modifications and upgrades can be easily implemented, accommodating changes in technology or system requirements. This adaptability is especially valuable in industries where machinery needs to keep up with evolving demands.

3. The Disadvantages of Mechanic Wiring

Despite its numerous advantages, mechanic wiring also has its drawbacks. One of the main concerns is the potential for wiring faults and failures. Poor installation, inadequate maintenance, or external factors such as vibration and temperature fluctuations can lead to short circuits, electrical fires, or even catastrophic system failures.

Moreover, troubleshooting and repairing mechanic wiring can be a daunting task, especially in complex systems. Locating and identifying faulty connections or damaged components requires specialized knowledge and equipment, often leading to increased downtime and maintenance costs.

4. Alternative Approaches to Wiring Systems

While mechanic wiring is widely used, alternative approaches have emerged in recent years. One such approach is the use of wireless technology. Wireless systems eliminate the need for physical wiring connections, offering greater flexibility and ease of installation. However, they may be less reliable in environments with electromagnetic interference or limited signal range.

Another alternative is the adoption of modular wiring systems. These pre-fabricated wiring solutions simplify installation and maintenance processes, reducing the risk of errors. However, they may not be suitable for all applications and may have limitations in terms of customization and future expansion.

5. Mechanic Wiring: A Detailed Overview

| Topic | Description |

|---|---|

| Types of Wiring | Explore the different types of wires and cables used in mechanic wiring, including their specifications and applications. |

| Electrical Components | Learn about the various electrical components involved in mechanic wiring, such as switches, relays, and connectors. |

| Wiring Design Principles | Discover the fundamental principles of designing an efficient and reliable mechanic wiring system. |

| Installation Procedures | Get insights into the step-by-step procedures for installing mechanic wiring in different mechanical systems. |

| Maintenance Best Practices | Learn about the recommended practices for maintaining mechanic wiring systems to ensure optimal performance and longevity. |

| Troubleshooting Techniques | Gain knowledge on troubleshooting common issues in mechanic wiring and how to identify and rectify them. |

| Safety Precautions | Understand the essential safety precautions to be followed during mechanic wiring installation and maintenance. |

| Industry Standards | Explore the industry standards and regulations governing mechanic wiring to ensure compliance and safety. |

| Future Trends | Discover the latest advancements and trends in mechanic wiring, including automation and smart systems integration. |

| Training and Certification | Learn about the training programs and certifications available for individuals pursuing a career in mechanic wiring. |

Conclusion

In conclusion, mechanic wiring plays a vital role in ensuring the proper functioning of electrical systems in various mechanical applications. While it offers reliability and flexibility, it also poses challenges such as potential faults and complex troubleshooting. Exploring alternative approaches and staying updated with industry standards can help overcome these challenges and harness the full potential of mechanic wiring. So, whether you are an electrical engineer, a mechanic, or simply an enthusiast, understanding mechanic wiring is essential in today’s electrified world.

Frequently Asked Questions (FAQ)

Q: What are the common signs of faulty mechanic wiring?

A: Some common signs include flickering or dimming lights, circuit breakers frequently tripping, and burning smells around electrical components.

Q: How often should mechanic wiring be inspected?

A: Regular inspections are recommended, with the frequency depending on the type of system and its usage. Generally, an annual inspection is a good practice.

Q: Can I perform mechanic wiring repairs myself?

A: It is strongly advised to seek professional assistance for wiring repairs, as improper handling can lead to safety hazards and further damage to the system.

Q: Are there any specific safety precautions to be followed during mechanic wiring maintenance?

A: Yes, some safety precautions include disconnecting power sources, wearing appropriate personal protective equipment (PPE), and following lockout/tagout procedures.